| Availability: | |

|---|---|

| Quantity: | |

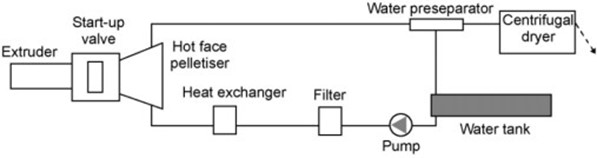

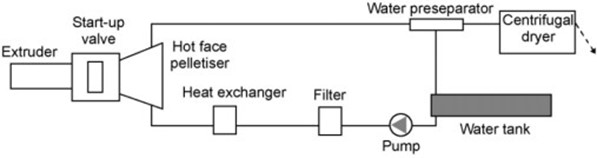

In underwater pelletizing system,the produced pellets are carried away as slurry in water for further cooling in transit, to the dewatering, screening, and drying equipment.underwater pelletizing consists of drive valve, die head, pellezing unit, bypass line, water recycling unit and centrifugal dehydrator.It is good for most of polymers,especially for TPU and TPV or similar elastomer, its advantage plays well.

(source from internet )

Excellent Pellet Quality: Underwater pelletizing produces high-quality pellets with uniform size and shape, resulting in consistent material properties and performance. This is particularly crucial for applications where product quality is paramount.

Heat-Sensitive Materials: If you are working with heat-sensitive thermoplastics or materials that degrade at high temperatures, underwater pelletizing is an excellent choice. The water bath rapidly cools the pellets, minimizing heat exposure and preserving material properties.

Reduced Dust and Fumes: Underwater pelletizing virtually eliminates dust and fumes during the cutting process. This is especially important for maintaining a clean and safe working environment, as well as for processing hazardous or sensitive materials.

High Throughput: The cooling effect of the water bath allows for faster production rates compared to some other pelletizing methods. If you need to achieve high throughput while maintaining pellet quality, underwater pelletizing is a suitable option.

In underwater pelletizing system,the produced pellets are carried away as slurry in water for further cooling in transit, to the dewatering, screening, and drying equipment.underwater pelletizing consists of drive valve, die head, pellezing unit, bypass line, water recycling unit and centrifugal dehydrator.It is good for most of polymers,especially for TPU and TPV or similar elastomer, its advantage plays well.

(source from internet )

Excellent Pellet Quality: Underwater pelletizing produces high-quality pellets with uniform size and shape, resulting in consistent material properties and performance. This is particularly crucial for applications where product quality is paramount.

Heat-Sensitive Materials: If you are working with heat-sensitive thermoplastics or materials that degrade at high temperatures, underwater pelletizing is an excellent choice. The water bath rapidly cools the pellets, minimizing heat exposure and preserving material properties.

Reduced Dust and Fumes: Underwater pelletizing virtually eliminates dust and fumes during the cutting process. This is especially important for maintaining a clean and safe working environment, as well as for processing hazardous or sensitive materials.

High Throughput: The cooling effect of the water bath allows for faster production rates compared to some other pelletizing methods. If you need to achieve high throughput while maintaining pellet quality, underwater pelletizing is a suitable option.

The most difference making us outstanding than other vendors is our strong processing capability .

Equipped with more than 50 sets of various types of machining equipment,core parts of the twin screw extruder are all manufactured at our own factory which makes the production cost and quality controllable .That's why our machine enjoy a high performance to price ratio

Gear box-self made

Torque rating grade: T/A3≤8 domestic standard major parts

New structure design and high precision grinding of hardened gear teeth to ensure the gear box long time high efficiency working.

Underwater pelletizing-self made

We manufacture the underwater pelletizing at our plant while other vendors usually buy from supplier.Therefore, the whole compounding line is matching well with each other at a high production efficency .The cost is saved for the customer by shortening the supply chain.What's more, the after-service is more insant and guaranteed by ourselves

Screw-self made

Screw element is with closely intermeshed design, block type and can be easily exchanged to suit different material.

Barrel-self made

Precision grade can reach to IT 6. It is benefit for energy reduction and block type design makes it possible for various combination.

The most difference making us outstanding than other vendors is our strong processing capability .

Equipped with more than 50 sets of various types of machining equipment,core parts of the twin screw extruder are all manufactured at our own factory which makes the production cost and quality controllable .That's why our machine enjoy a high performance to price ratio

Gear box-self made

Torque rating grade: T/A3≤8 domestic standard major parts

New structure design and high precision grinding of hardened gear teeth to ensure the gear box long time high efficiency working.

Underwater pelletizing-self made

We manufacture the underwater pelletizing at our plant while other vendors usually buy from supplier.Therefore, the whole compounding line is matching well with each other at a high production efficency .The cost is saved for the customer by shortening the supply chain.What's more, the after-service is more insant and guaranteed by ourselves

Screw-self made

Screw element is with closely intermeshed design, block type and can be easily exchanged to suit different material.

Barrel-self made

Precision grade can reach to IT 6. It is benefit for energy reduction and block type design makes it possible for various combination.

Customer Concerns

1.Are you a factory or trading company?

We're a factory, located in Lishui, Nanjing city with 20 years experience.

2.What's your advantages over other vendors?

The greatest advantage over other vendors is our strong processing capability .

Core parts of the twin screw extruder is all manufactured at our own factory which makes the production cost controllable.That's why our machine enjoy a high performance to price ratio.

Other advantages include:

Fast delivery

Competitive price

3.Where is your factory located? How can I visit there?

(2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed bullet train, then we will pick you up at Nanjing south railway station.

4.How can I know the status of my order?

We will keep you updated by photos and videos. Once the machine is completed and ready for shipment, we will inform you to come to inspect the machine.

5.How long is the deliver time?

Normally, 60 days from the date we receive your deposit.

6.How long is the warranty?

One-year warranty for the whole machine.

Customer Concerns

1.Are you a factory or trading company?

We're a factory, located in Lishui, Nanjing city with 20 years experience.

2.What's your advantages over other vendors?

The greatest advantage over other vendors is our strong processing capability .

Core parts of the twin screw extruder is all manufactured at our own factory which makes the production cost controllable.That's why our machine enjoy a high performance to price ratio.

Other advantages include:

Fast delivery

Competitive price

3.Where is your factory located? How can I visit there?

(2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed bullet train, then we will pick you up at Nanjing south railway station.

4.How can I know the status of my order?

We will keep you updated by photos and videos. Once the machine is completed and ready for shipment, we will inform you to come to inspect the machine.

5.How long is the deliver time?

Normally, 60 days from the date we receive your deposit.

6.How long is the warranty?

One-year warranty for the whole machine.

Model | Screw Diameter (mm) | L/D | Screw RPM | Main motor KW | Torque Grade T/N3 | Capacity kg/h |

SHJ-20 | 21.7 | 32-68 | 400/500/600 | 4 | 5.8 | 0.5-15 |

SHJ-30 | 30 | 32-68 | 400/500/600 | 11 | 5.8 | 5-50 |

SHJ-36 | 35.6 | 32-68 | 500/600/700/800 | 15-18.5-22 | 5.7 | 20-80 |

SHJ-42 | 41.2 | 32-68 | 500/600/700/800 | 22-30-37 | 5.7 | 50-120 |

SHJ-50 | 50.5 | 32-68 | 500/600/700/800 | 37-45-55 | 5.8 | 80-200 |

SHJ-63 | 62.4 | 32-68 | 500/600/700/800 | 55-75-90 | 5.8 | 150-350 |

SHJ-72 | 71 | 32-68 | 500/600/700/800 | 90-110-132-160 | 5.7 | 300-600 |

SHJ-85 | 82 | 32-68 | 500/600 | 160-200 | 5.7 | 600-1000 |

SHJ-92 | 91 | 32-68 | 500-600 | 250 | 5.8 | 840-1600 |

SHJ-135 | 133 | 32-68 | 650-750 | 400-500 | 5.8 | 1950-3250 |

Model | Pelletizer power KW | Centrifugal dewatering KW | Output kg/h |

UW5 | 2.2 | 1.5 | ~100 |

UW500 | 4 | 7.5 | ~500 |

UW1000 | 7.5 | 11 | ~1000 |

Model | Screw Diameter (mm) | L/D | Screw RPM | Main motor KW | Torque Grade T/N3 | Capacity kg/h |

SHJ-20 | 21.7 | 32-68 | 400/500/600 | 4 | 5.8 | 0.5-15 |

SHJ-30 | 30 | 32-68 | 400/500/600 | 11 | 5.8 | 5-50 |

SHJ-36 | 35.6 | 32-68 | 500/600/700/800 | 15-18.5-22 | 5.7 | 20-80 |

SHJ-42 | 41.2 | 32-68 | 500/600/700/800 | 22-30-37 | 5.7 | 50-120 |

SHJ-50 | 50.5 | 32-68 | 500/600/700/800 | 37-45-55 | 5.8 | 80-200 |

SHJ-63 | 62.4 | 32-68 | 500/600/700/800 | 55-75-90 | 5.8 | 150-350 |

SHJ-72 | 71 | 32-68 | 500/600/700/800 | 90-110-132-160 | 5.7 | 300-600 |

SHJ-85 | 82 | 32-68 | 500/600 | 160-200 | 5.7 | 600-1000 |

SHJ-92 | 91 | 32-68 | 500-600 | 250 | 5.8 | 840-1600 |

SHJ-135 | 133 | 32-68 | 650-750 | 400-500 | 5.8 | 1950-3250 |

Model | Pelletizer power KW | Centrifugal dewatering KW | Output kg/h |

UW5 | 2.2 | 1.5 | ~100 |

UW500 | 4 | 7.5 | ~500 |

UW1000 | 7.5 | 11 | ~1000 |