Nanjing Jieya will be attending 话题标签#Chinaplas2024 in Shanghai from April 23rd to 26th @ HALL 2.1 STAND C71. Diego Dell'Anna will be happy to welcome you and share our latest advances in modern 话题标签#Compounding, 话题标签#Recycling and Direct 话题标签#Extrusion lines and systems. Looking forward to see you t

Dear customers,NPE 2024 will take place at the Orange County Convention Center, May 6-10, 2024. Here we sincerely invite you to visit our booth: S26079E. Jieya team look forward to your coming :)

Closed Barrel SectionsThe most common barrel section design is, of course, the closed barrel section (Fig. 2). This barrel section fully encases the polymer melt on all four sides of the extruder with only a figure 8 opening through the center for the screws.

The design of the twin-screw extruder provides an advantage over other plastic processes. Full flexibility gives the process engineer the ability to configure the extruder to optimize the process and produce the best properties attainable.

Last sunday,we celebrated our 20th anniversary of establishment of Jieya company. Twenty years ago, armed with dreams, confidence, and unwavering determination, we embarked on a journey that carved out our own path in the vast business ocean. From a small group in the beginning to the large family w

Barrel MaintenanceProper maintenance of the twin screw extruder barrel is critical for performance and safety. The barrel should be kept clean and free of material buildup through regular cleaning procedures.Cleaning ProceduresAfter each job, thoroughly clean the barrel using purge compounds designe

In the process of compounding extrusion production, various chemical additives are often added to improve the overall performance of the products. However, this practice can lead to increased wear and corrosion of the twin-screw extruder screw and barrel. This not only results in a significant waste

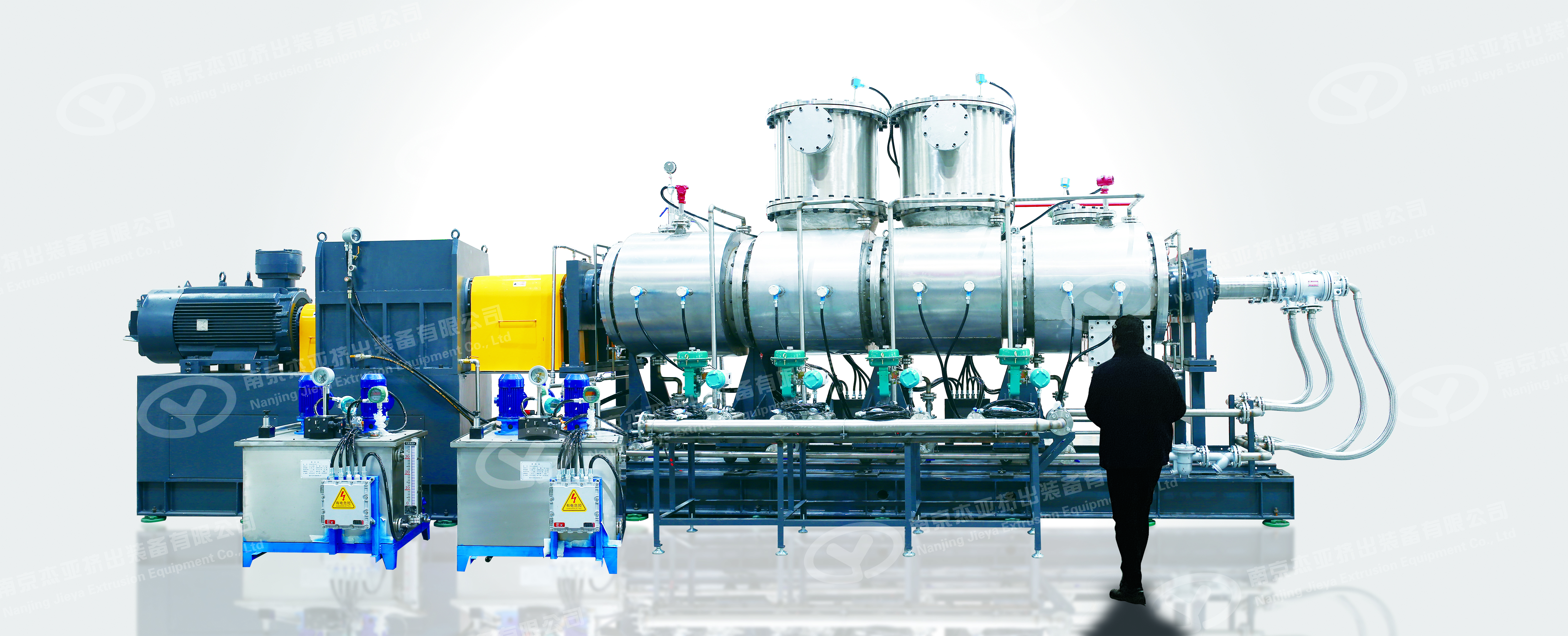

A devolatilization extruder is a specialized type of extrusion equipment used in the processing of polymers to remove volatile components from the material. Volatile components can include solvents, monomers, or other substances that are present in the polymer melt. The devolatilization process is c